Quality assurance, in its broadest context, is the systematic effort by a business to ensure that its end product satisfies its intended use, meets customers’ expectations, and is produced consistently with zero defects. Of course, how well a business manages a quality assurance program is based on the complexity of the end product, the number of processes required to make the product, and the exactness with which those individual processes are defined and controlled. Quality assurance is not a stand-alone system. It is merely part of an overall quality management system that must include process controls, checks and balances, compliance audits, continuous improvement, training, and employee engagement at every level. This overall process is most-frequently defined as Total Quality Management, which is the umbrella under which all of these other systems reside.

Quality management systems are not just limited to “manufactured” products. Total Quality Management concepts can be employed by any business that provides a service or product. In most cases, the product is only one piece of satisfying the customer. To meet consumer expectations, not only does the product have to perform as specified, but it must be backed by a responsive service team, proactive customer support, and conflict resolution services. A manufacturer that makes a product that performs 99.9% of the time as expected will continuously lose one-tenth of its market share if an unhappy customer is not properly appeased when there is an issue. A quality assurance program attempts to control and enhance every aspect of the customer experience including the product’s fitness for use as well as its reliability.

So why should any of this matter to you as a business owner providing a service or manufacturing a product?

The answer to this question probably seems obvious if you are world-wide producer of goods. Global competition requires that your product be the very best by customers’ standards, or it will be replaced with a competitor’s product. But what if you own a small consulting engineering firm, a hair boutique, or a chain of pizza delivery businesses in your town? You know what your customers want, right? You know what quality is all about, don’t you? It’s pretty simple isn’t it?

Well, maybe not.

If you have no systems in place to control your process or measure customer satisfaction, you are merely guessing at what the customer expects based on your own biases, and you will find no reason to change what you’re doing today to maintain or increase market share. Your business will continue to operate in the future the way it has in the past, and it will thrive, stagnate, or fail, and you will have no clue as to why it did any of those three things.

The driving force behind all quality control systems is customer feedback. Without the customer, you have no business. Unless the customer is satisfied with your product, you will not have a business for long. Unless you know what the customer wants and expects, you cannot possibly deliver it.

You don’t have to have a four-hundred page Quality Control Manual and an entire staff devoted to managing quality. But if you, as a business owner, don’t know what you’re controlling, you will have no idea how to change or modify it to improve the process. At a minimum, every business should have a list of suppliers of raw materials that have been evaluated and deemed acceptable, standard operating procedures for production, periodic retraining programs for employees, equipment standards and routine calibrations, control checks, and a method of measuring performance with its customers, and established methods of problem-solving, involving employees in the improvement process, and receiving and tracking customer feedback and satisfaction.

Let’s use the example of the pizza delivery business to see how all of this fits together:

On your first day, your four-person staff makes 100 pizzas and delivers them. Two of them come back with the drivers because they are stuck to the box, two people call to complain that the crust is unbaked, and a fifth calls to let you know that his pizza hasn’t arrived even though it’s been over two hours since he placed the order.

Does that mean your business is 95% successful? No. You honestly have no idea what it means at all. Were there many more unhappy customers that just didn’t complain? Of the five that did complain, are they just trying to get a meal for free, or were their complaints legitimate? What happened to the fifth customer’s pizza?

Unless you have a formalized feedback system, you cannot track complaints and issues over time and deal with recurring problems. Worse yet, if you have no process controls, you will have no idea where to start troubleshooting, and the problem will take longer to correct, costing you customers the entire time.

Do you measure your ingredients? Do you have a standard ladle for applying the sauce, a determined weight for the cheese, a written recipe that lists exactly what ingredients go on which pizza and in what order? When was the last time you checked the accuracy of the thermostat in your pizza oven? Are all of the complaints from people whose pizza was made by one particular employee? The more standardized processes you have in place, the faster you can respond to customer issues and correct the underlying causes.

Equally as important is how the complaining customers are treated. Did the manager personally speak with the caller whose crust was gooey? When the pizza came back stuck to the box, did the driver turn around immediately with a fresh pizza in hand and deliver it in pristine condition and give it to the customer for free? Or did the person answering the phone tell the unhappy customer that a task force was being formed to investigate the issue and that someone would be back in touch with him in two or three months?

The more questions that get asked and remain unanswered about any aspect of your product, the less control you have over it. It’s not necessary to control every aspect of your product, but you must select processes which you consider critical to your success and monitor them closely. Your customers will let you know very quickly if you’ve chosen to monitor the correct processes, or if changes need to be made or additional controls put in place to improve customer satisfaction.

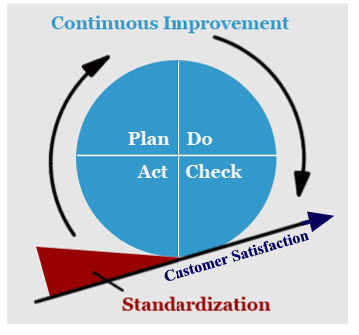

The drawing here, borrowed from the David Hutton Associates, Inc. website, perfectly illustrates the role that standards and quality assurance play in continuous improvement. To keep the continuous improvement wheel rolling up the hill of quality assurance and customer satisfaction, the plan/do/check/act cycle must continuously cycle forward. Standards are put in place to prevent the continuous improvement wheel from rolling back downhill.

The drawing here, borrowed from the David Hutton Associates, Inc. website, perfectly illustrates the role that standards and quality assurance play in continuous improvement. To keep the continuous improvement wheel rolling up the hill of quality assurance and customer satisfaction, the plan/do/check/act cycle must continuously cycle forward. Standards are put in place to prevent the continuous improvement wheel from rolling back downhill.

If the plan/do/check/act cycle stops, continuous improvement stops. If existing standards are in place, the process will not backslide, but will not continue up the customer satisfaction hill. If there are no standards in place, the wheel will immediately roll back downhill if there is any hesitation in the four-cycle process.

Every business can benefit from a quality assurance program. The detail to which it is applied is entirely up to the leadership of the company, but the more robust it is, the higher the chances are that a business will survive and even thrive in today’s economy. With the consumer now intimately linked into the social media world, a product and company can win and lose customers not linearly, but exponentially. Controlling the most-critical aspects of your processes sets you apart from your competition and makes good business sense.

back to Total Quality Management