ISO standards are really a Quality Management System with very specific rules on documentation and record-keeping. ISO is not a replacement for Total Quality Management. In fact, they can co-exist quite peacefully, since ISO is focused on consistency and record-keeping, while TQM is focused on employee involvement and product improvement. Both claim to be customer satisfaction and continuous-improvement oriented, but Total Quality Management is really the better forum for this. In fact, it is the goal of the TQM process.

ISO requires that the same things be done the same way all the time, and it is hard to squeeze customer satisfaction out of that process.

ISO Requirements

ISO is methodical and rigorous. It requires a company to take its production process and break it down into key steps. Each process is then analyzed to determine what the quality standards should be. Next, the company decides how it will measure each process to determine if it meets the quality standard they defined. Then, the approach to achieving that quality is documented (in the form of a Standard Operating Procedure), and finally, the company performs audits, internal and external, to ensure that the procedures are being followed. For each key process, you must look at 21 elements and decide which ones apply to that step, and then come up with a detailed plan to carry out and enforce the elements that do apply. Some of these elements include: Employee training, documentation, written standard operating procedures, training, management buy-in, tool calibrations and records, internal auditing, external auditing, document control, input material quality verification, and plans for handling non-conforming product.

The process sounds complicated, and it can be, depending on the level of quality control at a facility. The unusual thing is, ISO doesn’t care if your process is complicated or even whether it produces a quality product. All it cares about is that the company making the product follows the procedures they established, and that the end product is consistently like the last one and the next one. They “assume” that your product is already acceptable to the public, and that their mission is to ensure that product is consistent. The company makes it own rules, decides what to measure, how to track it, how to record it, and how to manage the records to be in ISO compliance.

ISO Standards Example

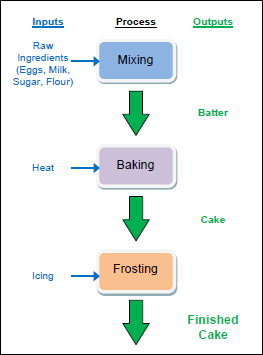

To try and make sense of all of this, let’s make a cake following (within reason) the standards that ISO requires: The Overall Process is: Making a Cake.

It has three sub-processes: Mixing, Baking, and Frosting.

Process One: Mixing.

The inputs are: Precisely measured quantities of milk, flour, eggs, vanilla, baking powder, baking soda, and sugar. The output is batter. The process is: Mix for 0:45 seconds or until there are no lumps larger than 1/16” in diameter.

Process Two: Baking.

The inputs are: Batter (poured to the proper height in the pan so it doesn’t overflow), and heat (an oven), pre-set to the correct temperature for baking. The process is: Bake for 40.0 minutes, or until a knife inserted in the center of the cake can be removed without any visual particles sticking to it. The output is a completed cake.

Process Three: Frosting.

The inputs are: Cake and icing, and the output is a finished cake. The process is: Frosting, using a 2” wide stainless steel spatula and distributing evenly until the entire visible portion of the cake has been covered.

That was the ISO process. Now, here are the ISO compliance steps:

- You have followed a written recipe for making the cake that has been documented, and kept in a controlled location (perhaps a locked recipe box) so that no one can change the recipe.

- In Process One, the ingredients would have been measured using a specific measuring device (Pyrex cup) that was calibrated annually.

- The device would have a sticker on it showing the last time it was checked for accuracy (calibrated to a known standard).

- The dimensions of the eggs would have to fall within a certain range, and the milk would have to be at a precise temperature before measuring (you might also state in your procedure – recipe – whether the milk is 2% or whole).

- The individual ingredients would be verified to be fresh (by comparing and documenting their expiration dates).

- The date used and the expiration date would be documented on the “assembly” sheet.

- The mixer’s beater speed would have to be checked on some frequency to ensure the mixing speed was the same every time, and the setting on the mixer would have to be documented (and another calibration sticker on the mixer).

- The baker would have had documented training in reading a recipe, proper measurement techniques, and mixer operator training.

- All of this information would be stored in a binder in a particular location for easy access.

- Plus, every so often, a certified baker would have to come to your house to inspect your calibration records, your process procedures, and your training credentials to ensure you were complaint with the rules you set up.

And that’s just to make the batter!

Keep in mind that, once the cake is done, it must taste and look like every other cake that was made before using that same recipe. ISO doesn’t assure quality, it assures consistency. If your recipe called for McCormick vanilla, and you used Kroger-brand, you would have just produced a non-compliant cake, which would have to put into an isolation area until a determination could be made as to what to do with it (rework, scrap, release with exceptions noted).

Note also that in the ISO process, the cake doesn’t have to taste good. This is where a complementary Total Quality Management system would work well. If the family thought your cake was lousy (negative customer feedback), you would have to modify the recipe (documenting each change for the ISO records), until your family liked it (customer satisfaction).

ISO is a rigorous method of ensuring a business has a Quality Management System. ISO certification tells other businesses and customers that they take great care to control the quality of their product, and can prove it. This can be of particular importance, especially to other businesses, who want to use this product as an input to their process, and need it to be exactly the same every time to ensure consistency.

back to What is ISO?